Any machine has its wear and tear, and issues that may affect its efficiency and hinder your work progress. It is better to keep in mind to regularly get your machine checked and serviced by a mechanic at least once a year. Try keeping the machine clean and change the needle often. Do not forget to use a good quality thread and keep your machine clean by protecting it from dust when not in use. Some common issues that can happen to an embroidery machine are:

- Needle causing holes

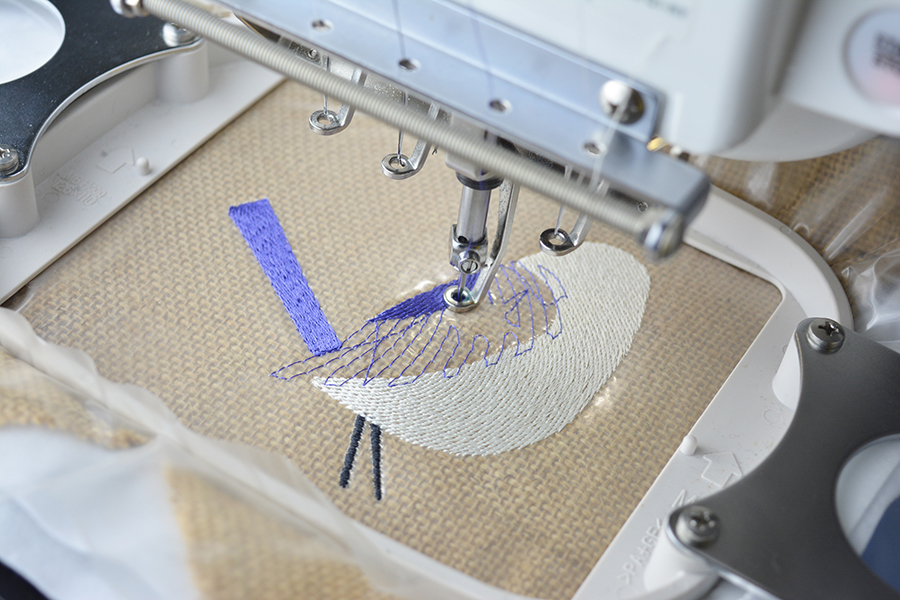

- In-House Embroidery Design is not being made properly

- Stitches are being skipped

- Needle Broken

- Upper thread broken

- Lower thread broken

- Machines is running slowly

- Machine is making noises

- Thread slipping out of the needle in the beginning

- It’s creating loops

These are some of thecommon issues that can happen to an Embroidery Backing machine; we have discussed some of the solutions below for some of them:

1. Stitches are being skipped:

What has caused this problem?

It can be a damaged, blunt, or bent needle. It can also be caused by an incorrect needle for fabric. There can be a case that the needle might not be inserted properly.

What can be done in this case?

We can replace the old needle with a new one. We can also try changing the needle according to the fabric.

2. Upper Thread broken

What has caused this problem?

This can happen because the machine isn’t threaded correctly, or there is a burr on the hook. Other reasons might include upper tension being too tight. It can also indicate the thread is stuck. There are two reasons which are possible like the needle is too small for the fabric, or the needle can be inserted incorrectly.

What can be done in this case?

We can thread the machine again or adjust the tension or do both. We can also try changing the hook for damage or insert a new needle.

3. Needle Broken:

What has caused this problem?

The reason a needle breaks is self-evident; either it is loose, or bent or too small for that fabric. Another reason can be the stitch position and presser foot did not match.

What can be done in this case?

We can insert a new needle, which is the correct size for the fabric. If not, this then use the correct presser foot for stitch type and then adjust the needle accordingly.

4. The machine is making noises:

What has caused this problem?

It can be caused either because the machine needs cleaning/oiling or the needle is blunt/damaged. In this case, the most common reason can be servicing and most people prefer that option too.

What can be done in this case?

The first thing you need to do in this case is clean feed teeth and shuttle areas. Another step could be to insert a new needle and check the manual on how to oil or call a qualified service agent to do the same. If not, have the machine serviced.

5. Thread slipping out of the needle in the beginning:

What has caused this problem?

The take-up lever pulls the thread when it lifts, or the trimming is done to close to the needle.

What can be done in this case?

The best option is to pull the thread down and hold it as the take-up lever lifts itself for the first stitch. These are some of the common issues that can happen to an embroidery machine, that is why regular upkeep becomes a necessity so that not much wear-tear is caused to them. Although yearly servicing is necessary, most of the issues can be solved by yourself if you have a clear understanding of the instruction manual. You might think that reading a manual can be an intensive laborious task with no fruitful result, but there is where you are entirely wrong. Reading an instruction manual is a task that, when completed, you know everything there is to know about your machine. Your machine’s features and what distinguishes it from others, what is the best it can do, what new things you can try, and lastly, what to when any of those problems mentioned above arise.